NANOTECHNOLOGY FOR LIFE™

Silicon Nanowires

Nanowires have been shown to be highly sensitive detectors of biomarkers. However, traditional fabrication methods are costly and yield devices with only a few nanowires. ASG's innovative approach enables the production of devices with millions of nanowires at a fraction of the cost, allowing for both highly sensitive detection and the simultaneous detection of multiple biomarkers on a single chip.

Award-Winning Technology: ASG has been awarded numerous awards which can be found on our News page.

Making Silicon Nanowires - ASG’s Process

ASG uses a process called MACE (Metal Assisted Chemical Etching) to produce silicon nanowire structures on the surface of silicon wafers.

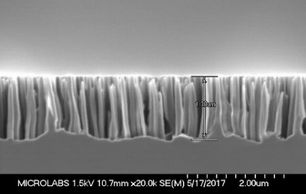

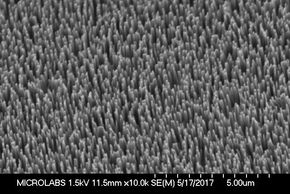

SEM Image of Nanowires on Biosensor Surface

SEM Image of Nanowires on Biosensor Surface

SEM Image of Nanowires on Biosensor Surface

SEM Image of Nanowires on Biosensor Surface

SEM Image of Nanowires on Biosensor Surface

SEM Image of Nanowires on Biosensor Surface

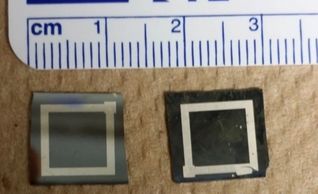

Sample Biosensor Chips

SEM Image of Nanowires on Biosensor Surface

Sample Biosensor Chips

Comparison to Other Approaches

Nanowires have been studied for use in the detection and measurement of proteins and other biological molecules, but the approach has not been widely applied. This is primarily because the designs used very expensive complex fabrication techniques and have only a few nanowires (1-5) per device limiting their utility.

Other Application of Nanowire Arrays in Solar PV

In solar photovoltaics, the process can be implemented using tools found in standard solar cell lines and can produce gains of 0.5% to 1.5% in absolute efficiency over baseline processes. This means no new capital is needed so there is only a modest upfront engineering cost in implementing the process. The cost at the cell level is estimated to be the same as standard cells on a $/Wp basis which means that costs are lowered at the module level and further downstream. The higher efficiency also means cells and modules are worth more. Perhaps most important today, our process can successfully texture multicrystalline wafers sawed with diamond wire, enabling the material and cost savings available from this improved technology. The combination of these effects will raise margins substantially for cell makers (we estimate approximate doubling). Licensing in the PV field is handled by our affiliate Advanced Silicon Technologies, LLC.

nanowire vs traditional solar cell

Other Application of Nanowire Arrays in Li-ion Batteries

Silicon is the anode material that has the highest lithium ion absorption capacity. However, silicon expands and contracts 4X when absorbing and then releasing lithium. In bulk silicon this results in the silicon turning into powder and the battery failing. Putting silicon in the nanowire form allows this expansion and contraction while maintaining a continuous conductive path down the nanowire .

Stay Tuned!

Sign up to hear new announcements.